Introduction

Think about the names of any five cars and you are sure to have a model of Ford on that list. That explains the brand’s popularity. How, when, where and why it came into existence are some questions that will be answered as you go through this biography of the brand’s mastermind and founder – Henry Ford. His life is what many of us have only dreamt about or read in fairy tales. In spite of the fame and riches he had garnered, he had his own share of difficulties too. His mantra to success can be traced from one of his own quotes:

“Life is a series of experiences, each one of which makes us bigger, even though sometimes it is hard to realize this. For the world was built to develop character, and we must learn that the setbacks and griefs which we endure help us in our marching onward.”

This is the story of a small farm boy from Michigan who grew up to become the founder of the Ford Motor Company, the richest man in America, a technical genius, a business legend, and the creator of the first mass produced automobile. He was the first to master and apply moving assembly line manufacturing for the mass production of affordable vehicles. By doing so, he succeeded in reducing hours of labour required to produce a vehicle and also multiplying the production. This accomplishment marked the amelioration of the US industrial production.

Let us take a look at the life and journey of this prodigy that made him the man that he was.

The Simplistic Early Life

Henry Ford was born on July 30, 1863, in his family’s farm, in Greenfield Township close to Detroit, Michigan. He was the eldest child of William Ford and Mary Litogot Ford, and was named after one of his paternal uncles. William Ford was born in County Cork, Ireland, to a family originally from western England. Mary Litogot Ford was born in Michigan, and was the youngest child of her parents who were Belgian immigrants. Her parents died when she was three and was adopted by her neighbours, Patrick O’Hern and Margaret Stevens. The O’Herns lived in a log cabin on a 91-acre Dearborn and Springwells Township farm.

35 year old William and 21 year old Mary got married in April 1961. Prior to his marriage, William had purchased the southern half of his father’s 80 acre farm in Redford Township, and later bought 80 acre in Dearborn Township. With his marriage to Mary, he acquired another 91 acre from Patrick O’Hern. Soon after their marriage, Henry’s parents, William and Mary shifted to the new white-painted huge seven-room frame-house that William had helped build on O’Herns’ land. Later four more rooms were added to it. It was in this frame-house that Mary delivered her children.

Mary and William had eight children out of which only five grew to adulthood, Henry being the eldest among them. Before Henry Ford, Mary and William begot a son who died in childbirth. After Henry Ford, his mother gave birth to John Ford (1865–1927), Margaret Ford (1867–1938), Jane Ford (1868–1945), William Ford (1871–1917) and Robert Ford (1873–1934).

His father William grew wheat and hay, tended his farm animals, cut wood, pruned his apple and peach orchard, and worked as a carpenter for extra income. Henry’s mother’s daily chores weren’t easy either. Her work included cooking, washing, cleaning, churning butter, making soaps and candles, knitting, gardening and so on. The young Henry Ford hated all this labour. It could be said that his loathe for hard manual labour increased his utmost liking for machinery, a means by which human labour could be minimized. As told by his sister, Margaret, she and her other siblings had to hide their mechanical toys from Henry Ford as he was always investigating things and dissecting them to check how they operated.

Henry’s father gave him mechanical projects to do on the farm. He preferred these projects rather than the farm work. For example, he liked to sharpen the saw used to cut wood and repair the plough rather than using them for labour.

Henry’s mother always instilled in him a strict sense of duty and to identify the do and don’ts in life. Though she didn’t believe in hitting her children to correct them, she also saw to it that they weren’t spoilt. She instilled in them noble principles and ideals. Henry was always very attached to his mother. She always advised Henry that he must not drink, smoke or gamble, and he followed this advice throughout his life. Once when his mother stopped talking to him for a day after catching a lie Henry became quite restless and vowed never to lie again.

The Inqusitive Toddler

On January 2, 1871, when Henry was seven and a half years old, he was supposed to join the school. But being the peak of winter it had snowed heavily, making it merely impossible to move out. Finding the snow too deep, his loving and considerate mother held him back home for a week; and so he started schooling on January 9 at the one-room Scotch Settlement School in Dearborn Township. However, during those days, schooling though being highly respected was to be considered only after chores on the farm, and thereby could only be attended during the slack season that came only after Christmas. Henry showed his mechanical ingenuity at school too, that often got him into trouble. He attempted to build a steam engine but burnt the school fence in the process. In those days, the worst possible punishment for a boy was to be made to sit between girls. Once when one of his male classmates was punished, Henry bored two holes in the boy’s bench during recess. He inserted a needle that stood upright in one hole, attached it to a string that ran through the other hole, and extended the string under his own bench. The tugs on the string brought forth shrieking results and what punishment befell Henry was only left to guess. Once he almost lost his finger trying to examine a hay chopper. When he was still a tiny tot, he was fascinated on seeing the steaming tea-kettle jiggling on the stove. So one day he filled an earthenware teapot with water, clogged its spout with paper, tied its lid tight to secure it, and held it close to the fire just to see what the steam could do. The kettle exploded and one of its fragments bruised Henry Ford’s head.

His face was also severely scalded, which left a faint scar that remained all his lifetime. In 1873, a ten year old Henry shifted to Miller School in the rural Springwells Township, northeast of Dearborn, Michigan, as he wanted to be with his favourite teacher, John Brainard Chapman, who had transferred from the Scotch Settlement School.

Then came a time when Henry faced a major tragedy in his life. At almost 13 years of age, he lost his mother. She had given birth to a stillborn on March 17, 1876, and followed by severe complications she breathed her last 12 days later on March 29. The loss of his dear mother shattered Henry and left the family in a state of shock and utmost grief. Though Henry’s sister, Margaret took care of all the chores at home and his father tried his best to fill their mother’s place, life was never the same without her. Henry Ford in the later part of his life had spoken about his mother’s absence as, “The house was like a watch without the mainspring.”

One of the most memorable incidents in Henry’s life took place the same year. In July 1876, a man named Fred Reden brought into the Dearborn region the first portable steam traction engine. One day, 12 year old Henry was on his way to Detroit taking a load of wool with his father, when he came across it for the first time. He was totally amazed to see this vehicle move on its own, as all other vehicles that he had seen were drawn by horses. It was actually meant for driving threshing machines and sawmills. This particular vehicle was just a portable engine and a boiler mounted on wheels with a water tank and coal cart trailing behind. Henry wasted no time to find out that the vehicle was made by Nichols, Shepard & Company of Battle Creek. The engine stopped to let his horse wagon pass; but before his father noticed, Henry jumped off the wagon to speak to Reden, who was operating the engine. In the midst of putting coal into the firebox of the steam engine to keep the steam up, Reden was more than happy to explain the entire working of the engine to the curious Henry. Over the next one year, Reden taught Henry how to ignite and operate the engine. In the later part of his life Henry Ford mentioned that it was this experience “that showed me that I was by instinct an engineer.”

He then began weaving ideas on innovative and easier ways of working on the farm as opposed to the traditional method that required heavy manual labour. He was sure that one day farmers would use machines to plough their fields rather than horse drawn ploughs. It was this engine that gave him ideas about automotive transportation.

Another memory that Henry Ford keeps close to his heart is the birthday gift that his father had given him on his 13th birthday – a pocket watch. As per his routine of dissecting mechanical objects, Henry dismantled the entire watch and reassembled it. Slowly and steadily he absorbed all the intricacies of its mechanism. By the age of 14, Henry Ford managed to put together a watch to keep time; and by the time he was 15, he could do almost anything with respect to repairing watches. He earned the reputation from his friends and neighbours as being a good watch repairman, and soon a small workbench near his window was covered with various watches for repair.

The interesting part was that though the delicate task of watch repairing needed appropriate tools to work with, all the tools he used were made of the crudest of things – a filed shingled nail became a screwdriver, a corset stay became a pair of tweezers, and so on. He felt that there was a great deal to be learnt by tinkering with things rather than merely studying about them in books. He always felt that machines are to a mechanic what books are to a writer.

At the age of 15, Henry left school but what remained unchanged in these years was his dislike to continue his life as a farmer. His father wanted him to be a farmer like him and take over the farm, but Henry refused by saying, “I never had any particular love for the farm. It was the mother on the farm I loved.” He wanted to leave for Detroit to further his quest for mechanical skills rather than continue his education.

Moving to Detroit and Back

In 1879, at the age of 16, Henry Ford left his home, walked six miles to the Michigan Car Company, a railroad-car manufacturer in Detroit, and took a job there for $1.10 a day. However, that did not last long as he was fired on the sixth day. It is said that he had angered older employees by making repairs in just half hour that the others usually took five hours and more. The same year, he moved to Detroit to work as an apprentice machinist at James F. Flower & Bros, a machine shop. Further on, in 1880, Henry shifted base to be an apprentice at the Detroit Dry Dock Company. It was a ship building company that also built engines used in ships. In the two years that he spent there, Henry familiarized himself with the working of internal combustion engines. Here he earned a mere $2.50 a week, which hardly covered his expenses for boarding and lodging. Therefore, he had to take up an evening job at Magill’s Jewellery shop where he was offered $2 a week. Initially, his duty was to just clean and wind the large stock of clocks in the shop, but very soon, he got the opportunity to pursue his passion – repairs of watches and clocks in the shop.

In 1882, 19-year old Henry who had completed his apprenticeship to become a certified machinist, returned to his father’s farm in Dearborn. Here, his neighbouring farmer, James Gleason, offered Henry to operate his small portable steam threshing machine – the Westinghouse Agricultural Engine. Though initially nervous, Henry in time proved to be adept in its operation and maintenance. Noticing his potential with the machine, Westinghouse Company offered him the job as the repairman for the company’s road engine. He was to operate and repair the engines sold in Michigan and northern Ohio. Hence, he spent the summers of 1883 and 1884 working with these engines; and in the winters trying to build a farm locomotive, but with little success.

Considering that he needed a business background to accomplish his plans for the future, he enrolled himself at the Goldsmith, Bryant & Stratton Business University in downtown Detroit on 1st December 1884. This was the only part of business education that he ever had. Although little is known about the exact course that he did, it is believed that here he was exposed to the rudiments of book-keeping, mechanical drawing, general business practice, penmanship and so on.

Though his training was limited and extended only for a few months, he made the most of it in the later part of his life.

Love, Romance, Wedding – a New Phase

The highly ambitious Henry Ford had his share of romantic inclinations too. Earlier, while working for his neighbour James Gleason, he was attracted to his beautiful daughter Christine and even proposed to get married to her. However, considering his financial status, she chose to marry a more financially sound man, Joseph Sheffery, who owned a blacksmith shop, carriage and horses.

The true love that entered Henry Ford’s life and that which progressed to marriage was Clara Jane Bryant. She was the oldest daughter of Martha and Melvin Bryant, born on April 11, 1866. They had seven more children after Clara was born. Similar to the Fords, they too were a well-off farming family. Clara being the oldest daughter helped her mother in all the household chores. Though Henry and Clara had grown up within eight miles of each other, they chanced upon a short conversation only in January 1885. However, they could not be regarded as total strangers as each of them knew the other’s family quite well, as Clara was Henry’s sister, Margaret’s friend for years and Henry was friends with Clara’s brothers. Their first meeting was at a New Year’s Ball in 1885 at the Martindale House – a local establishment where young people met and danced. Dancing being quite popular those days, Henry too, in an effort to socialize more, used to attend dancing sessions since the age of 19.

After they were introduced to each other at the Ball, Henry showed off his watch to Clara that displayed standard time and sun-time. She soon sensed that this young man was quite different from the other men around. This short tête-à-tête that the 21-year old Henry had with the 18-year old Clara on their first meeting was enough to leave a significant impression on his mind. However, it was only after almost a year that he got to meet her again. Soon love blossomed followed by frequent parties, dates and dancing sessions. However, they had to wait until April 19, 1886, to get engaged as Clara’s mother Martha felt her daughter was too young to be engaged before turning 20.

After Henry got engaged his father thought that this new phase in his son’s life may make him consider leaving machinery and take up farming as a profession. As an initiative for the same, he offered Henry a huge property that he had purchased in 1865. It was an 80-acre farmland with a vacant farmhouse on it. Henry accepted the property and also paid the property taxes beginning of 1887, but he had no intention of beginning cultivation there. There was a lot of wood to be cleared from the plot, so he set up a steam engine powered portable circular sawmill to help him with the task. He sold the lumber from his property at a price. He also helped clear woods from the plots of neighbouring farmers too. Prior to the wedding, the Fords and the Bryant brothers and sisters together renovated the old farmhouse on Henry’s property to make it liveable for the soon-to-be couple. Henry also built a machinist’s workshop there.

On Clara’s 22nd birthday dated April 11, 1888, she got married to Henry at her parents’ house. They then shifted to the renovated farmhouse in which they stayed for 13 months. In the meantime, Henry continued his timber business. He also set aside lumber from his land to be used for a new and bigger house that the couple had designed. They named it the ‘Honeymoon House’ or the ‘Square House’. Clara in particular took charge of the exact dimensions of the rooms and the interiors, and Henry along with another carpenter helped in the general carpentry. Amidst all these plans and routines, machinery had never left Henry’s mind. In the late summer of 1891, he shared with Clara his hopes to build a horseless locomotive powered by a gasoline engine. He also made a sketch of how it would work to make Clara understand better. An ideal wife that she was, Clara backed him to pursue his dreams. No wonder that he often referred to his wife as his ‘Believer’ as it was her trust and confidence through all the struggling years that helped him reach the pinnacle of success. He always knew that the farm was never his calling, and for more exposure in the field that he was interested in, he had to leave his farmland for Detroit.

A New Beginning in Detroit

In September 1891, Henry was offered the post of night operating engineer at a substation of the Edison Illuminating Company. Clara who loved country life was quite shocked at his decision to accept the offer and shift base to Detroit. The thought of leaving ‘Honeymoon House’ was heartbreaking for her. However, she did not want to thwart his ambitions and so without any complaints she supported all his decisions. Though the pay offered was just $40 a month, Henry was still anxious to join the company, as he saw it as an opportunity to learn more about electrical as well as steam engineering. This would in turn help him with the projects that he had in mind.

On September 25, 1891, 28 year old Henry and 25 year old Clara moved to downtown Detroit in a small rented accommodation. His shift timings were from six in the evening to six in the morning. So he went to work the very same day that he reached. During his spare time, he would work on building a gasoline engine ignited by electricity. Henry was quick to prove his calibre to his company. Within a month of his joining, he chanced upon a situation where in record time he repaired a steam engine that had broken down due to heavy electrical load. Had it not been for his ingenuity, the area would have had power loss for several days.

The very next month in November, his pay was increased by $5 making it $45 a month and in December it was further hiked to $50.

His salary was further augmented as he taught ‘machine tools practice’ at the YMCA during the winters of 1892 and 1893. Not only did he earn an additional $2.50 per session, but he also used the school shop to build, research and work on his projects. In July 1893, Henry got a transfer to the main Edison Powerhouse at Washington and State streets, with no raise in salary. In the meantime, his engine experiments were also worked upon simultaneously.

On November 6, 1893, their first child Edsel Bryant Ford was born. He was named after Edsel Ruddiman – Henry’s friend and classmate in the Scotch Settlement School. The birth of his son brought good luck to his life as within a few days of his birth, Henry’s salary was raised to $90 a month. Also, the very next month, i.e. on December 1, he was promoted as the Chief Engineer of the company. A few weeks later, the Ford family shifted to another rented house closer to his workplace. It was half of a duplex house at 58 Bagley Avenue. Henry was pleased with this new residence as it had a brick shed behind it, which served as a workshop for his experiments and inventions. Apart from this workshop, he and his friends rented a storage building close to the Edison building, to use it as a machine shop. This place was basically to put to test Henry’s experimental engines. His obsession with his personal experimentation on gasoline engines gave him little time to be with his wife Clara and baby Edsel.

Hard Work and Dedication Pays Off

The Christmas Eve of 1893 saw a breakthrough of his efforts. 30 year old Henry had finally managed to build a simple one cylinder gasoline engine. So happy was he with his success that he dragged the engine to the kitchen sink and asked Clara to assist him with its operation.

Hardly did he consider that there was a two month old baby sleeping in the adjacent room and that his wife was amidst preparations for the first Christmas of their son. Clara patiently did what her husband instructed her to do – to slowly pour fuel into the engine while he spun the flywheel. As the engine spurred, the excited and confident Henry made up his mind to build another bigger and better engine with two cylinders.

Two and a half years later, early morning on June 4, 1896, Henry successfully built his first, horseless and self-propelled wagon – the Quadricycle, in the workshop behind his house,. So immersed was he with this project that it was only after its completion that he realized that the doorway of the shed was too small to let the vehicle out. He had to use a pickaxe to crash the walls of the shed and widen its doorway to let the Quadricycle out. He was not the first to build such a vehicle, but the Quadricycle was the first of the long line of Ford automobiles that marked the beginning of Henry’s journey that led him to be the top-notch figure in automobile manufacturing.

Henry’s first masterpiece, the 500-pound Quadricycle, was a gas powered engine mounted on a simple frame and four bicycle wheels fitted on its sides. The vehicle used a four stroke two cylinder gasoline engine that generated a power of four horsepower (HP). It had only two gears for forward speeds – the first gear was about 10 miles per hour (16 km/h) and the second for 20 miles per hour (32 km/h). It had no reverse gear and steering wheel and instead, a tiller was used to steer the vehicle. It was a single seater with the fuel tank placed under the seat. The excited and thrilled Henry test drove the vehicle along the streets of Detroit that brought about a small crowd of curious onlookers on the road.

Taking Up New Risks and Challenges

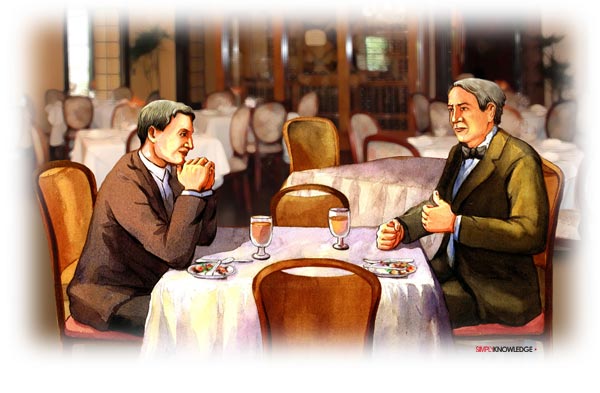

Henry had high regard for Thomas Alva Edison and considered him his idol. Though he worked at the Edison Illuminating Company, he had never got the opportunity to meet the great inventor till August 1896. This was when Henry was invited by his boss, Alexander Dow to a company banquet in New York in August 1896. Dow introduced him as a young man who had built a gas car. Edison was quite interested to hear all about it, and Henry sketched his ideas and spoke about his automobile plans to him. Edison favoured the gasoline-powered vehicle over the electric-powered ones. He applauded and encouraged Henry’s experiments with automobiles, and emphatically banged his fist on the table and said, “Young man, that’s the thing; you have it. Keep at it.

Electric cars must keep near to power stations. The storage battery is too heavy. Steam cars won’t do, either, for they require a boiler and fire. Your car is self-contained — carries its own power plant — no fire, no boiler, no smoke and no steam. You have the thing. Keep at it.” These words of encouragement motivated him to build a second and better model. Later in his life he had quoted, “That bang on the table was worth worlds to me. No man up to then had given me any encouragement. I had hoped that I was headed right, sometimes I knew that I was, sometimes I only wondered if I was, but here all at once and out of a clear sky, the greatest inventive genius in the world had given me a complete approval.”

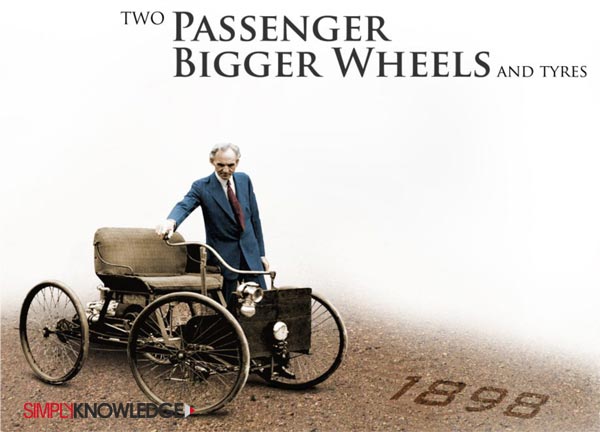

Henry began working on an improved version of the Quadricycle. To help him with the expenses of building a new car, he sold his Quadricycle for $200 to his friend Charles Ainsley. His second vehicle was completed in 1898. This car could carry two passengers and had bigger wheels and tyres. It ran quite well but was noisy when the car started and stopped.

Henry then began seriously considering the idea of opting manufacturing gasoline automobiles as his career. He realized that for the same he would need considerable financial help. Therefore, with the help of the Detroit Mayor, William C Maybury, he met local businessmen to talk about financing this new venture. Henry convinced a local lumber merchant, William H Murphy, in July 1899, to become a financial backer, when he took him on a 60 mile demonstration ride to Farmington, Pontiac and back to Detroit, in the car that he had built. The Detroit Automobile Company was formed on August 5, 1899, under Murphy’s leadership. The company had 11 stockholders, including Henry, who was appointed the Mechanical Superintendant. The manufacturing plant was to be located at 1343 Cass Avenue in Amsterdam.

His work of developing automobiles collided with his responsibilities at the Detroit Edison illuminating Company. His boss Dow offered him the position of General Superintendant of the company with a salary package of $1900 a year, provided he give up his passion for automobile building. But Henry had already made up his mind. He resigned from the company on August 15, 1899, to help run the Detroit Automobile Company. Considering the tight budget he was facing on the personal front, this would have been a tough decision; but his wife Clara stood as a pillar of support for all his decisions. In October 1899, the Ford family shifted to 1292 Second Boulevard that was close to the shops of the Detroit Automobile Company.

The first product of the new company was a delivery wagon that was completed in January 1900. It was successfully demonstrated on the streets of Detroit. Larger than the Quadricycle, this new vehicle used large carriage tyres. He bought the tyres from Harvey S Firestone, a salesman for the Buggy Company in Detroit. In the future, not only did Firestone and Henry do a number of businesses together, but also became good lifelong friends.

The Company was making slow but constructive progress. The first product of the company was a delivery wagon that was completed in January 1900. It was demonstrated on Detroit streets with considerable success. However, the major stockholders wanted quick profits rather than engineering a better automobile; and therefore pushed for a variety of vehicles. To that date, Henry had made only one car at a time, and moreover, he had his share of engineering problems too. Even though several cars were produced, the quality did not meet his standards, and they were too expensive to be sold. The company having spent almost $86,000 was eventually coming to a halt. Henry received his final cheque of $75 on October 29, 1900, and the company was officially dissolved in January 1901. Henry was jobless and had a family to take care of. Therefore to cut down on living expenses, he shifted to his father’s house on January 8, 1901 and occupied half of the property.

Ignoring Failed Attempts to Move On

Though Henry was no more with the Detroit Automobile Company, he still had some friends there. A few of the former stockholders of the company had retained a section of the Cass Avenue plant for Henry to build a car of his choice. For quite a while, he had been planning to come up with racing cars. For the same, he planned a new business strategy. He believed that publicizing his cars, and that being a racer, would encourage people to buy them and also help him establish his place in the automotive field. In this new mission, Henry put in all his efforts with the part-time assistance from his friends Ed Huff, Oliver Barthel and C Harold Wills. By mid 1901, a lightweight twin-cylinder racer with 26 HP was completed. To build this racer, it costed more than $5000, of which William H Murphy (Henry’s financial backer in the past) covered most of the cost. Henry drove the racer in a 10 mile race on October 10, 1901, at the Grosse Pointe equestrian track, defeating Alexander Winton’s (the famous Cleveland automobile manufacturer and fastest racer of that time) heavy 40 HP vehicle that had won many races earlier. During the race, his friend Ed Huff hung on to the running board and leaned in and out, whenever required, to balance the car when it took right and left turns on the track. Henry received a cash prize of $1000, a cut-glass punch bowl, and huge publicity.

His business strategy worked as many in Detroit were impressed with his car and also decided to support him financially. On the personal front, Henry, Clara and Edsel shifted from William Ford’s residence to a rented flat of their own at 332 Hendrie Street for $16 a month.

Winning the race gave Henry the much awaited hype that he needed. With this publicity and the help of William Murphy and some former members of the Detroit Automobile Company, the Ford Company was formed on November 30, 1901. Henry was titled the Chief Engineer and also owned one-sixth of the company stocks. Similar to his previous company, the partners of this company too wanted him to come up with more and more cars in order to recover their investment. However, Henry’s ideas differed; he wanted to come up with only one car at a time, especially another race car, to garner more attention and publicity. This led to disputes with his financers. Though William Murphy had financed the twin-cylinder racer, he was against Henry working on yet another racer, bigger than his previous one. What angered Henry further was that William Murphy was dealing with Henry M Leland, a renowned mechanical engineer and consultant. On the other hand, a wealthy bicyclist, Tom Cooper, who had witnessed Henry’s race victory, got in touch with him on March 3, 1902, to build him a racer. On March 10, 1902, he quit this company too, with the agreement that the company was to pay him $900, and no longer use his name. The same year Henry M Leland took charge of the company and renamed it to the Cadillac Motor Car Company, in honour of Antoine de la Mothe Cadillac, the founder of Detroit.

In May 1902, 39 year old Henry and Tom Cooper joined hands and settled with young Barton Peck for a portion of working space in his bicycle repair shop at 81 Park Place. Barton Peck was an automobile and racing enthusiast and the youngest son of George Peck, the President of Edison Illuminating Company. The project that was then worked upon in this new shared space was building two racers – the 999 for Henry, and the Arrow for Tom Cooper. The names were derived from two fast railroad trains. The first race they considered was on October 25, 1902, the Manufacturer’s Challenge Cup at Gross Pointe. The chief helpers to build the racers were C Harold Wills, Ed Huff, Charles Beebe and Gus Degener. Henry retained the promotional rights to the racers.

On August 20, 1902, Henry made a deal with a Detroit coal dealer, Alexander Malcomson, to market a simple designed motor car, as he did not want to lose the race at any cost, lest he lose his credibility. C Harold Wills made the sketches of the car. Alexander Malcomson put in $500 straight away along with the consent to offer additional investments required to complete a sample commercial vehicle. A partnership was signed to display the sample vehicle, in order to raise funds, to establish a company for the manufacturing of the commercial vehicle. As per the deal, C Harold Wills would receive $125 monthly which he would share equally with Henry.

In the meantime, the work on building the racers continued in full swing. Its engines were very huge, used four seven-inch cylinders and produced a horsepower between 80 and 100. The racers had no rear suspension and only one forward gear. Henry, Tom Cooper and Ed Huff tried Ford’s 999; but none of them were keen on riding it for the race. Therefore, Tom Cooper called his former bike racing protégé from Ohio, Barney Oldfield, to learn and ride the racer. Not only did he learn to ride the yellow-coloured 999 in a week’s time but also won the five mile race in a record time of 5 minutes and 28 seconds. This further glorified Henry’s name and also proved his point that he could build a fast motor car. After the race, Tom Cooper left Detroit with his racer, the Arrow, which was a mere duplicate of the 999, only that it was red in colour.

His main focus after the race was to come up with the sample commercial vehicle that was agreed upon. This vehicle designed by Henry and C Harold Wills was completed in December 1902. This new venture was named Ford & Malcomson Company Ltd. and had its operations at 81 Park Place. It was capitalized at $150,000 with 15,000 shares at a par value of $10 each. In April 1903, the automotive operation of the company was shifted to a larger building at 697 Mack Avenue. However, the company could not raise sufficient funds to handle its initial expenses and eventually, Alexander Malcomson’s rich uncle, John S Gray, agreed to put in an investment of $10,500; provided that he be made the President of the company. This incorporation was taken into account for the new company that took shape on June 16, 1903.

Founding of Ford Motor Company

On June 16, 1903, the new company – Ford Motor Company – was established. On that day incorporation papers for the Ford Motor Company were filed in Lansing, Michigan. On June 18, Ford & Malcomson transferred all their holdings to Ford Motor Company in exchange for 510 shares to be equally divided among the two partners, Henry Ford and Alexander Malcomson. A thousand shares of stock of an estimated value of $100,000 were divided between 12 investors that included Henry and Alexander. Initial investment in cash towards the new company was just $28,000 from the 12 stockholders. As promised, John S Gray was appointed the President. Henry Ford was titled the Vice President and Chief Engineer, with a salary of $300 per month. Finally, he had sufficient financial backing to build the car of his dreams - a vehicle that was strong, dependable, lightweight and inexpensive.

The company’s first car was the Model A that was built a little over a month after the company was formed. Hardly any machinery was required at the Mack Avenue plant; as all the parts were manufactured outside and only the assembling of the automobile was done at the plant. In June 1903, the necessary machinery for assembling the automobile was installed at the plant. Around 12 workers were hired at a pay of $1.50 to assemble 15 cars a day. Alexander Malcomson hired his clerk James Couzens as the bookkeeper for the Ford Motor Company. His efficiency soon helped him become a strong key player in the company. According to his cost analysis, the cost of parts which was $384 per car, and $20, the cost of assembly was added. Estimated sales costs were $150 per car, making the cost $554 without tonneau (an open rear passenger compartment, rounded like a barrel) or $604 with it.

Though the Ford Motor Company was well-financed in the beginning, its cash balance on July 11, 1903, after paying off for workers’ wages and machine parts, was a meager $225.60. But luck was in the new company’s favour, as it sold its first automobile, the Ford Model A – a two cylinder car, on July 15, 1903, to E Pfennig, a Chicago physician for $850.

The name Model A was given to two cars made by Ford Motor Company, one in 1903 and one beginning in 1927. The original Ford Model A was the first car manufactured in 1903, by the Ford Motor Company. Though Henry advertised the Model A as the ‘most reliable machine in the world’,

It had several issues common to vehicles of the era, including overheating and slipping transmission bands. A total of 1,750 cars were made from 1903 through 1904. The Model A was built by assembling an assortment of parts purchased from various suppliers. This car weighed 1,250 pounds and had a two cylinder engine developing 8HP. The engine was fitted under the front bench. The car had a steering wheel, and was a basic two-seater that could be converted to a four-seater tonneau model by adding a rear seat.

Within the next week of selling the first car, payments from five other buyers were received. Apart from this inflow of capital into the company, an addition amount of $5,000 was credited to its account with Albert Strelow, the company’s Mack Avenue landlord investing as a new stockholder. In a matter few months, the company had a bank balance of $23,000. Within the first three and a half months of operations, the Ford Motor Company made a profit of $36,957, and on November 21, it paid a dividend of 10 percent. By the end of the year 1903, the Ford Motor Company was firmly established; it outgrew the Mack Avenue plant and shifted to a huge well-planned and convenient building at Piquette and Beaubien streets that was 10 times larger than the Mack Avenue plant. By producing the Model A, the Ford Motor Company was able to build a profitable business and compete successfully with the other automobile companies for market share.

In 1904, the Ford Model C was manufactured which was a version of the first Ford Model A, but with a more modern look. It had a little more powerful engine and 6 inches longer wheelbase. Its production ended in 1905 with a total of 800 cars manufactured. The Model C had a flat-2 engine and was sold for $850, with the choice of converting it to a four-seater for an extra $100. The Model C had a protruding front ‘box’ like the present day cars, unlike the flat-front Model A. The engine remained below the seat and the gas tank was placed under the hood. Both Models A and C were produced at the same time, but the Model A could also be bought with the Model C engine equipped with a larger and more powerful engine. This was called Ford Model AC.

On January 9, 1904, 40-year old Henry participated in another racing event. He rode a four-cylinder Ford on a straight course over the frozen Lake St. Clair at New Baltimore. The area was cleared of snow and the ice was covered with cinders. Though the track looked smooth, it was quite a rough ride on it. During the course of the race, Henry hit a rift in the ice, at times went airborne in his vehicle and also landed askew a few times. However, he set an unofficial record of 36 seconds for the mile.

On March 8, 1905, Henry lost his father William Ford, due to natural causes. On the professional front, the company was faring fine and their financial conditions were improving. The same year, a total of 300 workers built 25 Ford cars per day. The profit for the year 1905 accumulated to $200,000, and the company opened a sales branch in St. Louis during the fall of 1905. On April 1, 1906, the company purchased a 57 acre expanse to build a larger plant later. By July 1906, production at the Piquette plant had risen to manufacturing a hundred cars a day.

The Ford Model K was introduced in 1906 and was an upscale automobile. It replaced the earlier Model B. The Model K was aimed at the top end of the market but it turned out to be a failure. The reason was its high cost (between $2500 and $3000) and poor quality. Its production ended in 1908 after 900 cars had been made. The same year, the Ford Model N produced by the Ford Motor Company was introduced as a successor to the Models A and C, as the company’s inexpensive entry-level line. The Model N differed from its predecessors as it was a front-engine car with a 4-cylinder engine. The car had a wheelbase size of 84 inches. It was a successful model and 7,000 cars were manufactured until its production ended in 1908. Priced at $500, the car was viewed as highly affordable at that time. Maroon was the only factory colour for the Model N. The Ford Motor Company was manufacturing its own engines for this model at a separate site and was considering a larger factory for the same. This model’s success was bothering Alexander Malcomson as he preferred larger and more expensive cars like the Model B and K. In the meantime, while still being the treasurer for the Ford Motor Company, he aimed for the presidentship of the Aerocar Company and also succeeded in this effort. Henry however was not pleased with this decision. He and other Ford board members demanded Malcomson to surrender his shares in Ford which he refused to comply. Hence, without his knowledge, Henry along with James Couzen’s help, set up the Ford Manufacturing Company, plainly to make parts for Ford Motor. Ford Manufacturing Company charged Ford Motor exaggerated prices, so as to shift Ford Motors’ profits to Ford Manufacturing. Malcomson, who was left with no choice, had to sell his stock in Ford Motor to Henry in 1906. This strategy ultimately made Henry Ford the major shareholder of the Ford Motor Company.

There was no stopping Henry’s success as more and more models of his cars followed. A higher trim level of the Model N was the red Model R. It was only produced from April 1907 to October 1907. A total of 2,500 cars were sold. The Model S was another variation of the Model N. It featured a more modern cowl, with hood and fenders that flowed into full running boards. Another noteworthy distinction was the optional extra third mother-in-law seat behind the front bench. The basic model sold for $700. Extra fittings like a convertible top, gas lamps, and umbrella holders were available. A total of 3,750 cars were sold between 1907 and 1909.

Confident about his foothold in the automobile manufacturing industry and about his upcoming models, Henry had quoted, “I will build a car for the great multitude. It will be large enough for the family, but small enough for the individual to run and care for. It will be constructed of the best materials, by the best men to be hired, after the simplest designs that modern engineering can devise. But it will be so low in price that no man making a good salary will be unable to own one – and enjoy with his family the blessing of hours of pleasure in God's great open spaces.” And true to his words, he came up with the Model T, the car that is regarded as the first affordable automobile. This model was powerful, strong, convenient, fast and most importantly, economical. It appealed to the middle and average working-class. The company produced this model from September 1908 to October 1927. In 1908, the Model T was sold for $825 and as the price dropped every year, the majority of American drivers learnt to drive on the Model T by the 1920s.

Along with success came its share of complexities too for Henry. He became the target of the Association of Licensed Automobile Manufacturers. With the help of George Baldwin Selden, an inventor/patent attorney, the association had acquired the rights to an automobile patent, applied for and obtained over a period of 25 years. Apart from that, the association was collecting a licensing fee for each vehicle manufactured by the Oldsmobile and Cadillac companies. Henry was denied membership of the association on the grounds for ‘business unreliability’ and further, a lawsuit was brought against him for patent infringement. The lawsuit went on for almost six years. Henry lost the first case against Selden and The Association of Licensed Automobile Manufacturers in 1909. Without delay, he appealed the verdict, and on January 9, 1911, the court reversed the decision in his favour. Henry became an instant celebrity around Detroit and an icon for many in the industry after he overcame this clash with the association.

Uniqueness of his Work Process and Company Management

Initially, the Ford Motor Company produced only a few cars a day due to the unorganised way that the workers assembled the cars. The growing market demand influenced Henry to build a new factory using standardized interchangeable parts and a conveyor-belt based assembly line. He had once said, “A Ford car contains about five thousand parts; that is counting screws, nuts and all. Some of the parts are fairly bulky and others are almost the size of watch parts. In our first assembling line we simply started to put a car together at a spot on the floor and the workmen brought to it the parts as they were needed in exactly the same way that one builds a house. When we started to make parts it was natural to create a single department of the factory to make that part, but usually one workman performed all of the necessary operations on a small part. The rapid press of production made it necessary to devise plans of production that would avoid having the workers falling over one another.”

In 1913, Henry introduced the first moving automobile assembly line at Highland Park. It became popular as it boosted mass production, which further led to the affordability of the Ford Model T, and the introduction of high earnings for Ford workers. Henry Ford was the first to master the moving assembly line and thereby improve other aspects of industry like reducing labour hours required to produce a single vehicle, and increase production numbers and parts. With regards to his assembly line, he had said, “I believe that this was the first moving line ever installed. The idea came in a general way from the overhead trolley that the Chicago packers use in dressing beef.”

According to Henry Ford, the assembly line was based on three simple principles, “The planned, orderly and continuous progression of the commodity through the shop; the delivery of work instead of leaving it to the workman’s initiative to find it; an analysis of operations into their constituent parts.”

That means,

One - The tools and the workers should be positioned in the sequence of the operation such that each component part travel the least possible distance during the process of finishing. Two - utilize work slides or other form of carrier such that the worker always drops the part in the same place when he completes his operation (that particular place should always be the most convenient place to his hand), and if possible have gravity carry the part to the next worker for his operation. Three - utilize sliding assembling lines by which the parts to be assembled are delivered at convenient distances.

In Henry Ford’s autobiography, he explained several advantages of the assembly line – The workers neither have to do heavy lifting nor stoop or bend for any task; They did not require any special training for their specific work as it was so simple that anyone could do it and it also provided employments to immigrants.

For the period of the late 1910s and early 1920s, along the banks of the Rouge River in Dearborn, the company began the erection of the world’s largest industrial complex in Michigan. The Ford Motor Company’s factory had everything required to build the vehicles – including a steel mill, glass factory and the first automobile assembly line. At the outset, to assemble a Model T car, it took 14 hours. Improvising on the mass production methods, Henry reduced the duration to 1 hour 33 minutes. This cut down the overall cost of each car and enabled Henry to undercut the price of other cars in the market. Between the period 1908 and 1916 the selling price of the Model T reduced to $360 from $1,000.

With the advancement in production, Henry was now able to market his cars to the general public. With the growth in productivity, Henry increased the pay of the workers from $2.50 to $5 per day and decreased the working hours in a week (to eight hours) while consistently lowering the Model T price. Though these goals appear unselfish; it has been argued that they were put into practice by Henry to reduce high employee turnover. He believed that this move would help him retain workers in the company and thereby save time to train new workers. Another strategy was that higher pay would make his company cars affordable for the workers and encourage them to buy it.

In February 1914, work of their new house – Edison Avenue, Detroit mansion – commenced. This was the Ford couple’s final home. In keeping with Henry’s love of nature, the residence was built with rough-hewn Ohio limestone to complement with the adjacent countryside. Jens Jensen, the noted landscape architect of the era designed the grounds that were transformed from farmland into a natural, native landscape. They shifted to this new house in January 1916. Meanwhile, James Couzen, who had become the General Manager of the Ford Motor Company by now, was a strong promoter of municipal operation of the city streetcar system. He spent extensive time involving in the city affairs and that bothered Henry Ford. Differences in opinion and other issues related led to Couzen resigning the Ford Motor Company on October 13, 1915.

One of the noteworthy contributions that Henry made towards society was offering educational opportunities. He began this social cause by opening the Henry Ford Trade School for Disadvantaged Boys, on October 25, 1916. He wanted to give young boys the foundation for a career in auto manufacturing, and to offer the same he opened the school on Woodward Avenue in Highland Park. Classroom time was divided between the regular high school subjects and the plant shops where the boys learnt the rudiments of shop work. Being a keen supporter of education, he opened 54 other educational facilities throughout the US, Canada and Europe.

He also came up with a sociological department in the factory that would inspect the life of workers and try to make it better. He was very much against labour unions as he considered that he knew what was best for his workers and their welfare. As much as he disliked trade unions, he hated wars as well.

Impact of World War I

On the outburst of the World War I in Europe, Henry Ford expressed his hatred for war and opposed it. He supported the decision of the Woman’s Peace Party to organize a peace conference in Holland. Following the conference, Henry was contacted by Jane Addams, Oswald Garrison Villard, and Paul Kellogg (America’s three leading anti-war campaigners), who suggested that Henry should sponsor an international conference in Stockholm to talk about ways that could bring the conflict to an end. He decided to send to Europe a boat of pacifists to check if they could agree upon an accord that would end the war. He employed the ship Oskar II that sailed with Henry Ford and members of the peace voyage on December 4, 1915, from Hoboken, New Jersey. In January 1916 the ‘Ford Peace Ship’ reached Stockholm, and a conference was arranged with representatives from Denmark, Holland, Norway, Sweden and the US. Howbeit, the conference was unable to negotiate a peace agreement as it was not possible to convince representatives from the warring countries to participate. All the more, Henry Ford left the ship just after it arrived in Europe.

When the war broke out, Henry had made up his mind that his company would never manufacture weaponry. But when the Navy proposed the mass production of small ships to chase German submarines, he approved to do so. It was his expertise in mass production that made the Federal Government approach him with this proposal. He began the ship building project on the River Rouge. In World War I he also ventured into the aircraft motor business with the production of the Packard-designed Liberty engine for the military, and completed 3,950 Liberty engines. In 1917, the company became a major supplier of weapons, especially the Liberty engine for airplanes, and anti-submarine boats. However, his ship building project did not turn into a successful venture as he did not complete any ships until after the World War I ended. The Navy was not pleased with the few ships he built, and that led to lengthy proceedings on the payments due, if any, that he would receive from the government.

Another development that year was that, Henry and his wife deeded the property to the Henry Ford Hospital incorporated on September 13, 1915. The opening meeting of the incorporators was held on September 21, 1915, and a board of trustees was elected with Henry Ford as President and his son Edsel as Vice President. During the war, Henry offered the hospital to the US government for use as an Army hospital. On October 26, 1918, the unfinished Henry Ford Hospital was temporarily transferred off to the US Army, and for the next 11 months, it was known as the US Army General Hospital No. 36.

Back at home, in 1916, Henry’s 23-year old son, Edsel Ford was encouraged to spend his spare time at home so that he did not pick up habits like smoking or drinking. These vices were not something that Henry would tolerate. But Edsel stayed at home for less than a year. On November 1,1916, he married Eleanor Clay in a simple ceremony held at Fair Lane. She was the niece of a department store magnate, JL Hudson. Post marriage, they shifted to the posh Indian Village area of Detroit, 12 miles from the Ford Estate. In 1917, Henry was blessed with his first grandson Henry II. Three more grandchildren followed – Benson (1919), Josephine (1923), and William Clay (1925). In 1918, Henry introduced and mass produced the Fordson tractor, which replicated his success with the Model T. Within a span of five years Henry captured 77 percent of the market in the US.

Post World War I, Henry Ford who at one point of time was only concerned about his business, now started shifting his focus to public affairs and politics. He joined the Democratic Party and in 1918 was narrowly defeated when he failed to win a seat in the US Senate. However, he continued to be outspoken on political issues, and to support his ideas and plans, he acquired a very controversial newspaper, the Dearborn Independent, an anti-Jewish publication that many found offensive. As per Henry’s views, the newspaper blamed Jews for starting wars in order to profit from them. Such articles in the paper gave rise to claims of anti-Semitism against Ford Years later, he signed a statement apologizing for the articles.

On one hand where he was being condemned for his liberal political views, Henry left no opportunity wherein he could offer aid to his workers. Apart from the wartime production changes, the end of the World War I brought with it the inflation of household goods in the US. Henry perceived this situation as an opportunity to help his workers, while also letting his company make a profit. On December 1, 1919, he made an official announcement to come up with the Ford Commissary. The object of the commissary was to offer high quality and low cost household goods to the workers at the Ford Highland Park plant. The commissaries gained through the use of private labels (Ford) and bulk purchasing, particularly of standard products. The Highland Park commissary was the first, largest and the longest operating commissary of over a dozen established by the Ford Motor Company. These were located far and wide; from the Upper Penninsula of Michigan to the Brazilian jungles.

Passing on the Presidency

On December 30, 1919, 46-year old Henry Ford formally resigned as President of his company and gave control to his 26-year old son, Edsel Ford. However, even though he was appointed the new President, all his decisions had to be approved by Henry Ford first, before it could be worked upon. He always wanted a more modern automobile to replace the Model T but his proposal was constantly overruled by his father. Edsel’s mechanical and managerial abilities were satisfactory and he had a great talent to design vehicles. He also strengthened Ford Motors’ overseas production extensively and worked to modernize the company’s cars – like the introduction of hydraulic brakes.

By March 1920, the company completed building the gasoline rail car. Its engine was a four cylindered horizontally opposed composition that developed 75 HP. In July, the same year, Edsel purchased the Detroit, Toledo & Ironton Railroad. This was a steam railroad system stretching from Dearborn to the Ohio River. Therefore, now he had his own 456 miles track to test his car. In the 1920s, the Ford Motor Company witnessed a rapid growth. In 1925, Ford was producing 10,000 cars every 24 hours – 60 percent of America’s total output of cars. By the mid 1920s, the Fords were among the top four richest people in America. Post World War I, Henry Ford became aware of the prospective of mass air transportation. His Tri-Motor aircraft that was nicknamed ‘The Tin Goose’, paved way for another new market, the airline travel. The Tri-Motor first flew on June 11, 1926, and was the first successful US passenger airliner, accommodating around 12 passengers in a rather uncomfortable fashion. The first three Tri-Motors built seated the pilot in an open cockpit.

The Ford Motor Company built 199 Tri-Motors from 1926 through 1933.

Nevertheless, Henry Ford’s decision of not coming up with any new car models was letting rival companies eat up on their market share. By 1926, Model T sales had crashed, and Henry Ford was almost sure that the end was at hand. On May 25, 1927, he unexpectedly declared the end of production of the Model T. The same year, he also shut down the Highland Park factory for six months. By 1927, as the sales were dropping, the company decided to come up with a new model – the second car to be given the name Model A. The relocation of the assembly line in 1927 from Highland Park to the River Rouge Facility in Dearborn fulfilled Henry’s idea of an industrial complex that incorporated all aspects of automotive production. The first automobile to be completely assembled here was the new Model A of 1927.

By the time it went into production, the River Rouge facility had become the main Ford Manufacturing facility. Through the design stage of the new Model A, Henry Ford saw to it that the mechanical quality and reliability was perfect. He let Edsel develop the body design and make a few changes (like the inclusion of four-wheel mechanical brakes and a sliding gear transmission). The resulting model struck gold as it turned out to be a huge commercial success, selling over four million within the first four years of production. This is regarded as the last success that Henry Ford saw in his company.

In the year 1928, Henry Ford was awarded the Elliott Cresson Medal, also known as the Elliott Cresson Gold Medal. It is the highest award given by the Franklin Institute “for some discovery in the Arts and Sciences, or for the invention or improvement of some useful machine, or for some new process or combination of materials in manufactures, or for ingenuity skill or perfection in workmanship.” Henry Ford was awarded for the engineering category for revolutionising automobile industry and industrial leadership.

On October 21, 1929, with a celebration in Dearborn, Michigan, Henry Ford honoured the 50th Anniversary of Thomas Alva Edison’s invention of the light bulb. This event also included the dedication of The Edison Institute of Technology (later renamed Henry Ford Museum) and Greenfield Village. Edison was 82 and his Menlo Park laboratory was shifted to Greenfield Village and restored by Henry Ford.

Onset of Downfall

On Tuesday, October 29, 1929, the stock market crashed that led to the Great Depression (a period in the 1930s marked by severe economic hardship). The initial phase of the ‘Great Depression’ terribly affected not only the Ford Motor Company but the entire US vehicle production. Even the sale of the successful ‘Model A’ dropped by 50%, from 1930 to the end of 1931. To give impetus to company sales, Edsel Ford, the Company’s President, announced the roll-out of Ford Model B. It was an updated version of the Model A car. It was later replaced by the Model 48. The company also began producing a similar car with Ford’s new flathead V‑8 engine. Though commonly known as the Ford V‑8, it was marketed as Model 18. Other than the engine, it was virtually identical to the Model B. However, the company wasn’t yet ready for mass production of the new models, and the engine had not been exhaustively tested too. Hence, the buyers had to deal with long delays in getting the new models, and then repeated breakdowns too. Henry Ford lost about $75 million in 1932. He had to make up for the loss with severe pay cuts and layoffs. This led to the occurrence Ford Hunger March, sometimes called the Ford Massacre, on March 7, 1932. It was a march of Detroit Unemployed Council and the Auto, Aircraft and Vehicle Workers of America starting from Detroit to the Ford River Rouge Complex in Dearborn, the company’s largest factory. There were 14 demands that the marchers proposed to present to Henry Ford. A few of these were demands for rehiring of the unemployed, health care, an end to racial discrimination, winter fuel for the unemployed, abolishment of company spies and private police, and the right to organize unions. The protest turned ugly in no time due to the acts of the Dearborn Police Department and security guards employed by the Ford Motor Company. Head of Ford’s security, Harry Bennett, drove his car into the retrieving crowd and fired; the police too open fired. The march caused four workers being shot to death and several injured. The Ford Hunger March was a significant part of a chain of events that ultimately led to the unionization of the US auto industry. Henry Ford had refused to cooperate with the National Recovery Administration; a 1930s government agency that organized and administered codes of fair competition for businesses and industries. The Great Depression also led to the closure of Tri-Motor airline manufacturing. The Tri-Motor sales dropped from a whooping 86 a year in 1929 to only two sales in 1932. The poor sales resulted in the shutting down of the Ford Airplane Division in 1933.

One of the other reasons for the impending downfall was the Battle of the Overpass, an incident that took place on May 26, 1937. Here the labour organizers clashed with Ford Motor Company security guards at the River Rouge Plant complex in Dearborn, Metro-Detroit, Michigan. Henry Ford declined to recognize the United Automobile Workers (UAW), and brutally limited their efforts to organize the workers of his company. He was of the firm belief that he cared and knew his workers’ needs better than any trade or labour unions. Henry was adamant about his resolution to not agree to the union’s demands. In 1938, Henry Ford suffered a stroke, but dominant that he was, he continued to exercise control of his company rather than entrusting the powers to his son Edsel Ford. The latter was the President only in namesake.

Nine years later, there was a 10-day sit down strike by 40,000 Ford workers. This added to his wife’s constant spat over the union issue. She ultimately told him, “I am leaving you after fifty years, if you do not support our son Edsel, and sign off on the Union Contracts.” Henry Ford was therefore compelled to sign a collective bargaining agreement with the United Auto Workers union on April 11, 1941.

Impact of World War II

During World War II (1939-45) Henry initially made pacifist statements, but later changed his mind and contributed greatly to the war effort. The Ford factories were converted to plants that constructed war machines. Once the US entered the war, Henry Ford ordered the Ford Motor Company to construct a vast new purpose-built factory at Willow Run near Detroit, Michigan. He re-entered the aviation market with the production of the B-24. The first B-24 came out in October 1942. The Consolidated B-24 Liberator was an American heavy bomber, designed by Consolidated Aircraft of San Diego, California. This factory had the largest assembly line in the world. Mass production of this bomber went in full swing by 1943, where peak production had reached to one B-24 per hour and 650 per month in 1944. For World War II, the Rouge plant also produced jeeps, tanks and bombers.

The Deteriorating Years

Though a strict entrepreneurial father, the loss of his son, Edsel, shattered Henry Ford. The budding entrepreneur died on May 6, 1943, at the age of 49 due to cancer of the stomach. He was buried at Woodlawn Cemetery in Detroit, Michigan. Each his children inherited many shares in the Ford Motor Company, and all the three sons joined the family business.

In spite of having suffered a stroke in 1938, Henry Ford had to now resume the presidency of the company. However, his deteriorating health did not allow him to abide by the company responsibilities any further. Thus, the eldest of Edsel’s son, Henry Ford II, succeeded his grandfather Henry Ford as President of Ford Motor Company on September 21, 1945. This time around the senior Ford couldn’t cross-check on his grandson’s company decisions as he had during his son’s time. The 83-year old elderly and ailing Henry Ford was bed-ridden by 1947. The same year, alone with his wife and a servant, he breathed his last on April 7, in Fair Lane, his Dearborn estate, due to cerebral haemorrhage. A communal viewing was held at Greenfield Village where around 5,000 people per hour filed past the casket. The funeral service was also arranged in Detroit’s Cathedral Church of St. Paul, and Henry Ford was buried in the Ford Cemetery in Detroit. In 1950, Henry Ford’s life partner and ardent supporter of all his decisions, Clara Ford left the mortal world probably to be by her husband’s side again.

Following the demise of Henry Ford, a foundation was formed to govern his enormous fortune. This foundation gave substantial support to numerous projects related to arts, medicine and other important areas of American life.

Organisational Changes and Growth of Ford Motor Company

Henry Ford’s eldest grandson, Henry II, served as President from 1945 to 1960 and as Chairman and CEO from 1960 to 1980. In the meantime, on January 17, 1956, Ford Motor Company became a publicly traded corporation with the public sale of common stock shares. The company was listed on the NYSE on March 7, 1956. The Ford family maintains about 40 percent controlling interest in the company, through a series of Special Class B preferred stocks.

In 1946, Ernest R Breech was hired to become the company’s first Executive Vice-President, then Board Chairman in 1955. Robert McNamara, who had joined the company as the manager of planning and financial analysis, grew within the company through a series of top-level management positions to be appointed as the Company President on November 9, 1960, by the then Chairman, Henry Ford II. He was the first company head selected outside the Ford family. However, in less than five weeks of becoming President, he left the company to join John F Kennedy’s cabinet, as the Secretary of Defense. In 1960, Robert McNamara was appointed the President of Ford by Chairman Henry Ford II. In 1979 Philip Caldwell became Chairman of the company. He was succeeded by Donald Petersen in 1985. From 1990 to 1993, Harold Poling served as Chairman and CEO. Alex Trotman was Chairman and CEO from 1993 to 1998. He was followed by Jacques Nasser to be the Chairman and CEO from 1999 to 2001. William Clay Junior, Henry Ford’s great grandson, was elected the Chairman in September 1998. Following the ouster of then-CEO Jacques Nasser, William Clay Ford Junior became the CEO on October 30, 2001 until September 5, 2006. He named Alan Roger Mulally as his successor but remained as the Executive Chairman of the company. Alan Roger Mulally is currently the President and CEO of the company. During the late-2000s recession, the company experienced its share of struggles. However, it returned to profitability under Alan Roger Mulally.

Today Ford Motor Company, apart from the manufacture of automobiles, is also engaged in other businesses. The two sectors that the company operates in are the Automotive and Financial services. The Automotive Sector includes Ford North America, Ford South America, Ford Europe and Ford Asia Pacific Africa. The Financial Services includes Ford Motor Credit Company and Other Financial Services. Ford North America includes the sale of Ford, and Lincoln-brand vehicles and related service parts in North America, together with the associated costs to develop, manufacture, distribute and service these vehicles and parts. Ford Motor Credit Company includes automobile-related financing, leasing and insurance. Other Financial Services includes a variety of businesses including holding companies and real estate.

At present the company has manufacturing operations globally, including in the US, Canada, Mexico, China, the UK, Germany, Turkey, Brazil, Argentina, Australia and South Africa. It also has a cooperative agreement with the Russian automaker GAZ.

The Man Ever-Remembered

Henry Ford, the legend considered as one of America’s leading businessmen, is credited even to this day for helping to build America’s economy during the nation’s susceptible early years. He was also announced the ‘Car Entrepreneur of the Century’ on December 18, 1999 in Las Vegas. This honour was an international award given to the most influential car entrepreneur of the 20th century. The election was administered by the Global Automotive Elections Foundation.

No doubt that as long as there are automobiles in this world, Henry Ford’s name will be remembered and his legacy will live for eternity. It did not take rocket science for Henry Ford to build his business empire. The simple man, with simple upbringing believed in a very simple business strategy that he followed that for life. In his own words, he said –

“There is only one rule for the industrialist and that is: Make the best quality goods possible at the lowest cost possible, paying the highest wages possible.”

In today’s business scenario not many would follow this business concept and probably that is the reason why we don’t have many Henry Fords among us – a man who not only aimed for the sky but also embraced as many as he could in that journey.

Next Biography

Related Events And Inventions